GFG

JIANGSU JINLING DRYER

84193990

| Availability: | |

|---|---|

| Quantity: | |

Product Description

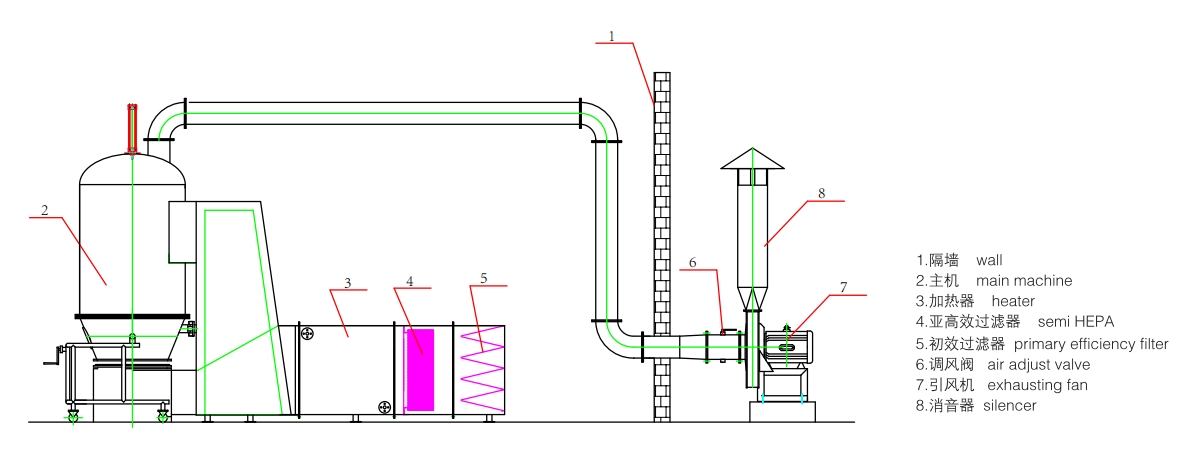

◆Once the air is filtered and heated, it enters the main body of the dryer from the bottom, and passes through the mesh plate of the hopper and the material. In the drying chamber, the fluidized drying state is formed by stirring or negative pressure. After the dust is collected by the cloth bag,the moisture is discharged by the induced draft fan so that the material can be dried in the end.

◆Depending on how the moisture contained in the material evaporates during the drying process and how the specific gravity of the material changes after the drying process completes, we have different air volumes, air pressures and temperature ranges in different sections to meet the requirements of drying.

◆We can install an agitator in the drying bed to enhance the efects of fluidization, avoid material agglomeration due to its high moisture content, prevent any shutdown caused by excessive feed, and speed up the drying process.

◆A gyclone dust collector can be insalled at the back of the boiling chamber for automatic material ollection, and a cloth bag dust scrubberor a water film dust scrubber can be added as well according to the requirements of our customers .

◆This machine is suitable for batch or semi-continuous fluidized bed drying or cooling of low temperature and heat sensitive materials.

◆For drying highly toxic or dusty materials, our company has specially designed the type of machine with the fully sealed and automaticoperation.

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you

Jiangsu Jinling Drying Technology Co., Ltd. was founded in 2000, as an innovation-oriented enterprise specialized in advanced technology.We have over 30 years of experience in machine manufacturing. We have achieved more than fifty national level patents and ten provincial level certificates for new high-tech products. There are more than 120 employees in our factory, Jinling is professionally engaged in designing, manufacturing over 30 series of drying equipment, environmental protection equipment, evaporation & concentration equipment and dry granulation equipment which are widely used for environmental protection field, chemical field, food field, national defense field etc.

Jinling is the qualified manufacturer of special pressure vessel, established the biggest drying & granulating testcenter in China, and passed the examination of ISO 9001, ISO 14001, OHSAS18001 and CE certification.Jinling's equipment has been spread all over China and has been exported to over 40 countries.

1. Q: Jiangsu Jinling Drying Technology Co., Ltd is a manufacturer, trading company or a third party?

A: We are a manufacturer, Our company established in 2000.

2. Q: Where is your factory located?

A: Jinling is located in Changzhou city, Jiansu province, China. it is In the middle of Shanghai and Nanjing.

3. Q: How can I go to your factory?

A: You can fly to shanghai Pudong or Hongqiao international airport directly, then take the high speed train to Changzhou station (just 1 hour from Shanghai to Changzhou by train) and we arrange to pick you up at Changzhou station to go to our company. Yutong company is around 30km away from Changzhou station.

If you are in China now, you can fly to Changzhou Benniu airport, or take train or bus to Changzhou city directly .

We sincerely welcome to visit our company at any time.