Jiangsu Jinling Drying

841939990

| Availability: | |

|---|---|

| Quantity: | |

Product Description

A fermentation tank is a critical piece of equipment widely used in industries such as food, beverage, pharmaceuticals, and biotechnology. Designed specifically for mixing and fermenting raw materials, it plays a vital role in ensuring the quality and efficiency of the fermentation process. This equipment is engineered to handle complex biological or chemical reactions, ensuring that raw materials are evenly mixed while creating an optimal environment for fermentation.

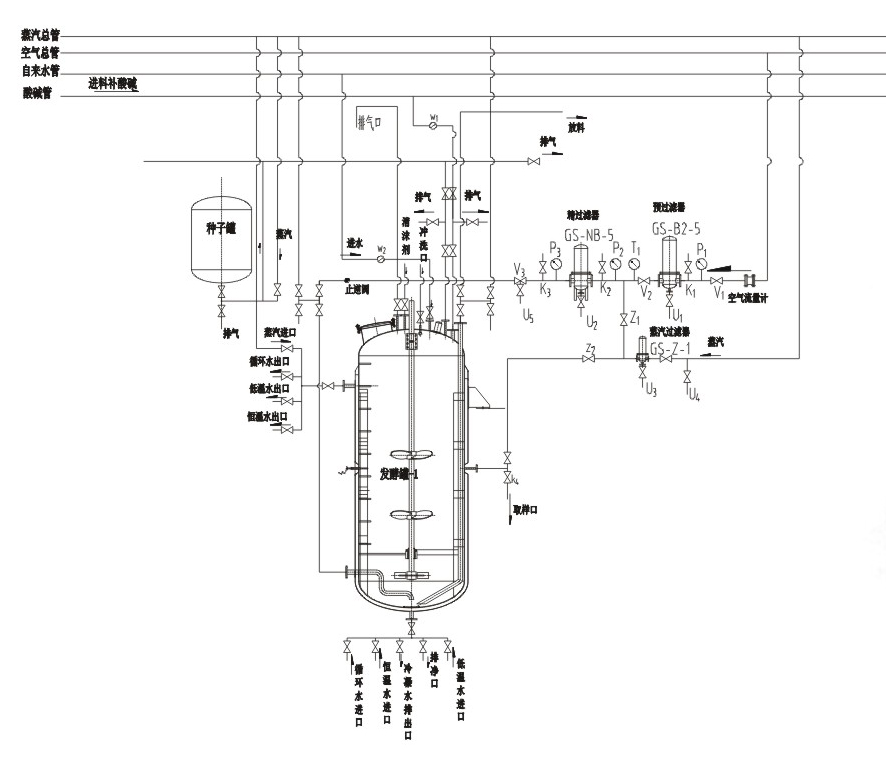

One of the most notable features of this fermentation tank is its internal circulation structure, which enhances the efficiency of mixing and fermentation processes. This structure ensures that materials inside the tank are uniformly combined and fermented under controlled conditions. The tank is equipped with advanced systems to handle foam production, aseptic conditions, and temperature regulation, making it an indispensable tool in modern production lines.

The fermentation tank is designed with an internal circulation structure, which sets it apart from other traditional fermentation equipment. This innovative feature allows for continuous movement and blending of raw materials within the tank. The internal circulation ensures that all ingredients are evenly distributed, preventing uneven fermentation and ensuring consistent product quality.

The movement of raw materials within the tank also helps to disperse and break down foams that are generated during the mixing process. Foam formation is a common challenge in fermentation, as it can interfere with the efficiency of the process and compromise the final product. By incorporating a system that actively disperses and eliminates foam, this fermentation tank ensures a smooth and uninterrupted fermentation process.

Inside the tank, an aseptic respiration system or an aseptic fermentation system with compression is installed. These systems are crucial for maintaining sterility during the fermentation process. Fermentation often involves the growth of microorganisms under controlled conditions, and any contamination can lead to spoiled products or even hazardous outcomes in certain industries.

The aseptic respiration system ensures that the gas exchange needed for fermentation occurs without introducing any external contaminants. Similarly, the aseptic fermentation system with compression provides a sterile and controlled environment for microorganisms to thrive. These features make the fermentation tank ideal for industries where sterility is paramount, such as pharmaceuticals and biotechnology.

Unlike many fermentation tanks that are covered with a jacket for temperature control, this tank operates without a jacket. Instead, the circulation of heating and cooling is accomplished through the direct application of heat or cooling to the media inside the tank. This design offers several advantages:

Efficient Heat Transfer: Direct heating or cooling ensures faster and more efficient temperature regulation.

Simpler Maintenance: Without the need for a jacket, the tank is easier to clean and maintain.

Space-Saving Design: The absence of a jacket reduces the overall footprint of the tank, making it ideal for facilities with limited space.

Industries that rely on temperature-sensitive fermentation processes include:

Food and Beverage: For brewing beer, fermenting wine, and producing yogurt.

Pharmaceuticals: For producing antibiotics and other biologically active compounds.

Biotechnology: For developing enzymes, biofuels, and other innovative products.

Many manufacturers offer customization options for fermentation tanks, allowing businesses to tailor the equipment to their specific needs. These options may include:

Different sizes and capacities.

Additional monitoring and control systems.

Enhanced materials for greater durability and hygiene.

In conclusion, the fermentation tank is a highly versatile and efficient piece of equipment that is essential for modern industrial processes. Its internal circulation structure, advanced foam control mechanisms, aseptic systems, and innovative temperature regulation design make it an indispensable tool for industries ranging from food and beverage to biotechnology and pharmaceuticals. By investing in high-quality fermentation tanks, businesses can ensure consistent product quality, improve efficiency, and meet the stringent requirements of their respective industries. Whether you are producing beer, yogurt, antibiotics, or biofuels, the right fermentation tank can make all the difference in achieving success.

Model | FXG0.05 | FXG0.1 | FXG0.2 | FXG0.5 | FXG1.0 | FXG2.0 | FXG5.0 | FXG10.0 | FXG20.0 | FXG50.0 | FXG60.0 |

Volume(L) | 50 | 100 | 200 | 500 | 1000 | 2000 | 5000 | 10000 | 20000 | 50000 | 60000 |

Diameter (mm) | 400 | 500 | 500 | 700 | 900 | 1100 | 1400 | 1800 | 2300 | 3100 | 3200 |

Height (mm) | 990 | 1135 | 2330 | 2600 | 2900 | 3800 | 4545 | 5250 | 6550 | 8550 | 10730 |

Pressure Inside Tank (MPa) | 0.2 | ||||||||||

Pressure Inside Jacket (MPa) | 0.3 | ||||||||||

Number of Blade | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 |

Mixing Speed(rpm) | <360 | <360 | <360 | <220 | <180 | <136 | <136 | <125 | <110 | <110 | <110 |

Mixing Power (kW) | 0.55 | 0.55 | 0.75 | 1.1 | 3 | 3 | 5.5 | 11.5 | 23 | 55 | 55 |

Heating Type | Jacket Heat-exchange tube | ||||||||||