Jinling Technology specializes in thin film evaporators, featuring high heat transfer efficiency and short heating times (5-10 sec), ideal for heat-sensitive materials. Equipped with centrifugal rotors and movable scrapers, it enhances evaporation by 40-69%. Various scraper types are available for different needs. The system supports automatic, continuous production under sealed conditions, requiring minimal space and easy maintenance. Ideal for industries like pharmaceuticals and food processing.

Jiangsu Jinling Drying

841939990

| Availability: | |

|---|---|

| Quantity: | |

Product Description

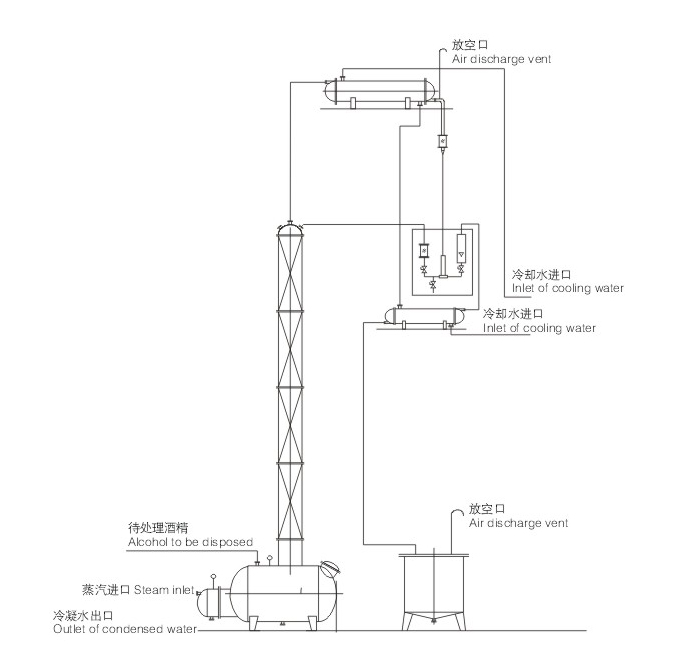

Ethanol’s lower boiling point allows it to be separated from water and other components in a solution. By carefully controlling the heating temperature, ethanol vaporizes selectively without boiling off water.

The distillation tower enhances the ethanol concentration by separating impurities and non-ethanol components. This ensures that the final product meets the required purity standards for industrial use.

After vaporization, the ethanol vapors pass through a condenser where they are cooled and transformed back into liquid form. The recovered ethanol can then be reused, reducing waste and improving cost-efficiency in the distillation process.

The ethanol distiller is widely used in the pharmaceutical industry to recover and purify ethanol used in various processes, ensuring cost-effectiveness and adherence to quality standards.

In the food industry, the distiller is used to recover ethanol utilized in flavoring, preservation, and other applications, helping maintain product integrity and safety during production.

The chemical industry leverages the ethanol distiller to distill solvents like methanol and ethanol for use in chemical reactions, synthesis, and other industrial processes.

This equipment is also applicable in light engineering industries where ethanol recovery plays a crucial role in production efficiency and sustainability.

Depending on user requirements, dilute ethanol solutions with a concentration of about 30° can be distilled into ethanol with a concentration of 90-95°. The flexibility in adjusting concentration levels ensures the equipment meets diverse industrial needs.

For higher ethanol purity in the final product, the reflex ratio can be increased. However, this adjustment may reduce the overall product rate. The ability to modify the reflex ratio allows for tailored distillation processes based on specific quality requirements.

The ethanol distiller can be equipped with optional accessories to enhance functionality and adapt to specialized processes. This customization capability ensures the equipment provides optimal performance in varying industrial scenarios.

The ethanol distiller is an essential tool for recovering and purifying ethanol and other solvents across industries such as pharmaceuticals, food processing, chemicals, and light engineering. Its ability to achieve high ethanol concentrations with adjustable reflex ratios and its customizable design make it a reliable and efficient solution for diverse industrial applications.

Model | Diameter of | Volume | Height of | Volume | Condensing Area | Cooling | Heat | Recovery Capacity | Recovery |

T-200 | ф200 | 1000 | 6000 | 1000 | 5 | 1 | 3.0 | 45-50 | >90 |

T-300 | ф300 | 1500 | 7000 | 1000 | 9 | 1.5 | 6.0 | 90-110 | |

T-400 | ф400 | 2000 | 7000 | 2000 | 11 | 2.2 | 6.5 | 180-200 | |

T-500 | ф500 | 2500 | 7000 | 2000 | 18 | 4 | 10 | 190-310 | |

T-600 | ф600 | 2500 | 7500 | 2000 | 25 | 6 | 15 | 430-450 | |

T-800 | ф800 | 3000 | 7500 | 2500 | 45 | 8 | 26 | 750-780 |

Note: Feed concentration: 30% -80%, reflux ratio depends on the feed concentration.

Pictures of Ethanol Distiller

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you

Jiangsu Jinling Drying Technology Co., Ltd. was founded in 2000, as an innovation-oriented enterprise specialized in advanced technology.We have over 30 years of experience in machine manufacturing. We have achieved more than fifty national level patents and ten provincial level certificates for new high-tech products. There are more than 120 employees in our factory, Jinling is professionally engaged in designing, manufacturing over 30 series of drying equipment, environmental protection equipment, evaporation & concentration equipment and dry granulation equipment which are widely used for environmental protection field, chemical field, food field, national defense field etc.

Jinling is the qualified manufacturer of special pressure vessel, established the biggest drying & granulating testcenter in China, and passed the examination of ISO 9001, ISO 14001, OHSAS18001 and CE certification.Jinling's equipment has been spread all over China and has been exported to over 40 countries.

1. Q: Jiangsu Jinling Drying Technology Co., Ltd is a manufacturer, trading company or a third party?

A: We are a manufacturer, Our company established in 2000.

2. Q: Where is your factory located?

A: Jinling is located in Changzhou city, Jiansu province, China. it is In the middle of Shanghai and Nanjing.

3. Q: How can I go to your factory?

A: You can fly to shanghai Pudong or Hongqiao international airport directly, then take the high speed train to Changzhou station (just 1 hour from Shanghai to Changzhou by train) and we arrange to pick you up at Changzhou station to go to our company. Yutong company is around 30km away from Changzhou station.

If you are in China now, you can fly to Changzhou Benniu airport, or take train or bus to Changzhou city directly .

We sincerely welcome to visit our company at any time.