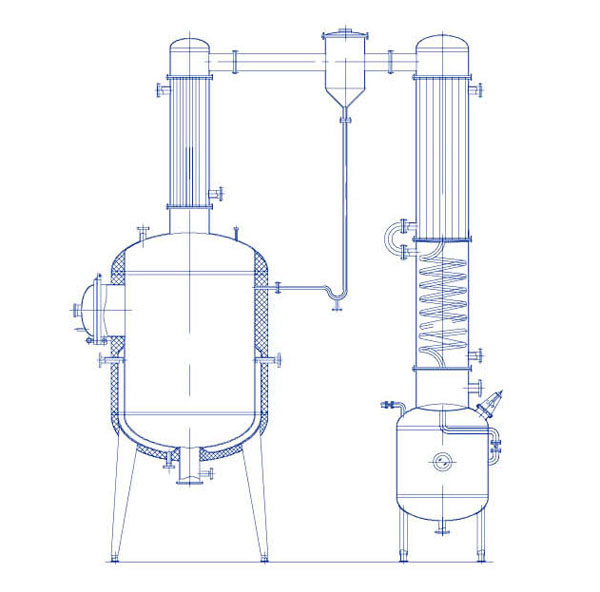

Vacuum Evaporator: Comprises evaporator tank (jacket heating), condenser, vapor-liquid separator, cooler (coil), and receiver. Used in pharmaceutical, food, chemical industries for liquid concentration, alcohol recovery, and simple reflux extraction.

Jiangsu Jinling Drying

841939990

| Availability: | |

|---|---|

| Quantity: | |

Product Description

A vacuum evaporator is a highly specialized piece of equipment widely used in industries such as pharmaceuticals, food production, and chemicals. This advanced machine is designed for the concentration of liquids, recycling of alcohol, and even simple reflux extraction. Its unique design and functionality make it a versatile and efficient solution for processes requiring evaporation under controlled conditions.

At its core, the vacuum evaporator operates by reducing the pressure inside the system, which in turn lowers the boiling point of liquids. This allows for evaporation to occur at lower temperatures, preserving the quality of heat-sensitive substances and improving energy efficiency. With its robust construction and multi-functional components, the vacuum evaporator is a cornerstone of modern industrial operations.

The vacuum evaporator is primarily composed of five key components, each playing an essential role in the evaporation process:

Evaporation Tank with Jacket Heating Structure: The evaporation tank is the central component of the system. It features a jacket heating structure, which ensures uniform heat distribution around the tank. This design allows the liquid inside to be heated efficiently and evenly, facilitating consistent evaporation. The jacket heating system is particularly beneficial for applications requiring precise temperature control.

Condenser: The condenser is responsible for cooling and condensing the vapor generated during the evaporation process. By transforming the vapor back into a liquid state, the condenser helps recover valuable substances, such as alcohol, ensuring minimal waste and maximum efficiency.

Vapor-Liquid Separator: The vapor-liquid separator is a critical component that separates the vapor from the remaining liquid. This ensures that only the vaporized components reach the condenser while preventing liquid carryover, which can compromise the efficiency of the process.

Cooler with Coil Structure: The cooler, equipped with a coil structure, is designed to further reduce the temperature of the condensed liquid. The coil structure provides a large surface area for heat exchange, ensuring rapid and effective cooling. This feature is particularly important for applications where the final product must be stored or processed at lower temperatures.

Receiver: The receiver collects the final condensed liquid, such as concentrated extracts or recovered alcohol. It is typically designed to be easily emptied and cleaned, ensuring efficiency and hygiene in industrial operations.

The pharmaceutical industry relies heavily on vacuum evaporators for a range of applications, including:

Concentration of Active Ingredients: The vacuum evaporator is used to concentrate active pharmaceutical ingredients (APIs) by removing excess solvents. Its ability to operate at low temperatures ensures that heat-sensitive compounds remain stable, preserving their therapeutic properties.

Alcohol Recovery: During the production of herbal extracts or other pharmaceutical products, alcohol is often used as a solvent. The vacuum evaporator efficiently recovers this alcohol, reducing production costs and minimizing waste.

Reflux Extraction: Simple reflux extraction processes, commonly used in pharmaceutical manufacturing, can also be performed using a vacuum evaporator. This ensures efficient extraction of valuable compounds from raw materials.

In the food industry, the vacuum evaporator plays a crucial role in processes such as:

Concentration of Juices and Syrups: The vacuum evaporator is widely used to concentrate fruit juices, syrups, and other liquid food products. By evaporating water at low temperatures, it preserves the flavor, color, and nutritional value of the final product.

Recovery of Aromatic Compounds: During the evaporation process, valuable aromatic compounds can be recovered and reused, enhancing the quality of food products.

Production of Concentrated Dairy Products: Vacuum evaporators are essential for producing concentrated dairy products, such as condensed milk, by removing excess moisture without compromising the product's quality.

The chemical industry benefits from vacuum evaporators in several ways:

Concentration of Chemical Solutions: The vacuum evaporator is used to concentrate chemical solutions, ensuring that the desired compounds are efficiently isolated and prepared for further processing.

Solvent Recovery: Many chemical processes involve the use of solvents, which can be expensive and environmentally harmful if not properly managed. The vacuum evaporator recovers these solvents for reuse, reducing costs and environmental impact.

Handling of Heat-Sensitive Chemicals: The low-temperature operation of the vacuum evaporator makes it ideal for processing heat-sensitive chemicals, preventing degradation and ensuring product quality.

Versatility: Its ability to handle a wide range of applications, from liquid concentration to solvent recovery, makes it a versatile tool.

Energy Efficiency: By operating under vacuum conditions, the evaporator minimizes energy consumption, reducing operational costs.

Preservation of Heat-Sensitive Materials: The low-temperature operation ensures that heat-sensitive compounds remain stable, preserving their quality.

Environmental Benefits: The system’s ability to recover and reuse solvents reduces waste and minimizes the environmental impact of industrial processes.

High Productivity: The efficient design and advanced components of the vacuum evaporator ensure high productivity, meeting the demands of large-scale operations.

In conclusion, the vacuum evaporator is a vital piece of equipment for industries that require efficient and precise evaporation processes. With its advanced components, such as the jacket-heated evaporation tank, coil-structured cooler, and vapor-liquid separator, the vacuum evaporator delivers exceptional performance across various applications.

Whether it’s used in the pharmaceutical industry for concentrating active ingredients, in the food industry for producing high-quality syrups, or in the chemical industry for recovering solvents, the vacuum evaporator consistently meets the needs of modern industries. Its versatility, energy efficiency, and ability to preserve heat-sensitive materials make it an indispensable tool for ensuring high-quality output and sustainable operations.

Model | JN50 | JN100 | JN200 | JN300 | JN500 | JN700 | JN1000 | JN2000 | |

Vapor Pressure (MPa) | < 0.25 | ||||||||

Eveporating Ability (kg/h) | 20 | 40 | 60 | 80 | 100 | 130 | 160 | 350 | |

Heating Area (m2) | 0.4 | 0.6 | 0.8 | 1.1 | 1.2 | 2.0 | 2.5 | 5.5 | |

Condensing Area (m2) | 1.2 | 1.7 | 2.4 | 3.0 | 3.2 | 3.6 | 4.5 | 14 | |

Cooling Area (m2) | 0.25 | 0.35 | 0.45 | 0.6 | 0.7 | 0.85 | 1.1 | 3 | |

Storage Capacity (L) | I5 | 45 | 60 | 76 | 100 | 125 | 140 | 185 | |

Energy Consumption (kg/h) | 23 | 46 | 70 | 92 | I15 | 150 | 185 | 403 | |

Vacuum Level (MPa) | -0.08 | ||||||||

Vessel Type | Category I pressure vessel | ||||||||

Weight (kg) | 410 | 470 | 605 | 715 | 862 | 1015 | 1250 | 2600 | |

Overall Size (Reference) (mm) | L | 1200 | 1350 | 1700 | 1800 | 2100 | 2400 | 2390 | 2730 |

W | 600 | 750 | 800 | 950 | 1200 | 1300 | 1300 | 1500 | |

H | 2200 | 2200 | 2700 | 2850 | 3400 | 3400 | 3720 | 4700 | |

Pictures of Vaccum vaporator

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you

Jiangsu Jinling Drying Technology Co., Ltd. was founded in 2000, as an innovation-oriented enterprise specialized in advanced technology.We have over 30 years of experience in machine manufacturing. We have achieved more than fifty national level patents and ten provincial level certificates for new high-tech products. There are more than 120 employees in our factory, Jinling is professionally engaged in designing, manufacturing over 30 series of drying equipment, environmental protection equipment, evaporation & concentration equipment and dry granulation equipment which are widely used for environmental protection field, chemical field, food field, national defense field etc.

Jinling is the qualified manufacturer of special pressure vessel, established the biggest drying & granulating testcenter in China, and passed the examination of ISO 9001, ISO 14001, OHSAS18001 and CE certification.Jinling's equipment has been spread all over China and has been exported to over 40 countries.

1. Q: Jiangsu Jinling Drying Technology Co., Ltd is a manufacturer, trading company or a third party?

A: We are a manufacturer, Our company established in 2000.

2. Q: Where is your factory located?

A: Jinling is located in Changzhou city, Jiansu province, China. it is In the middle of Shanghai and Nanjing.

3. Q: How can I go to your factory?

A: You can fly to shanghai Pudong or Hongqiao international airport directly, then take the high speed train to Changzhou station (just 1 hour from Shanghai to Changzhou by train) and we arrange to pick you up at Changzhou station to go to our company. Yutong company is around 30km away from Changzhou station.

If you are in China now, you can fly to Changzhou Benniu airport, or take train or bus to Changzhou city directly .

We sincerely welcome to visit our company at any time.