ZJG

JIANGSU JINLING DRYER

84193990

| Availability: | |

|---|---|

| Quantity: | |

Product Description

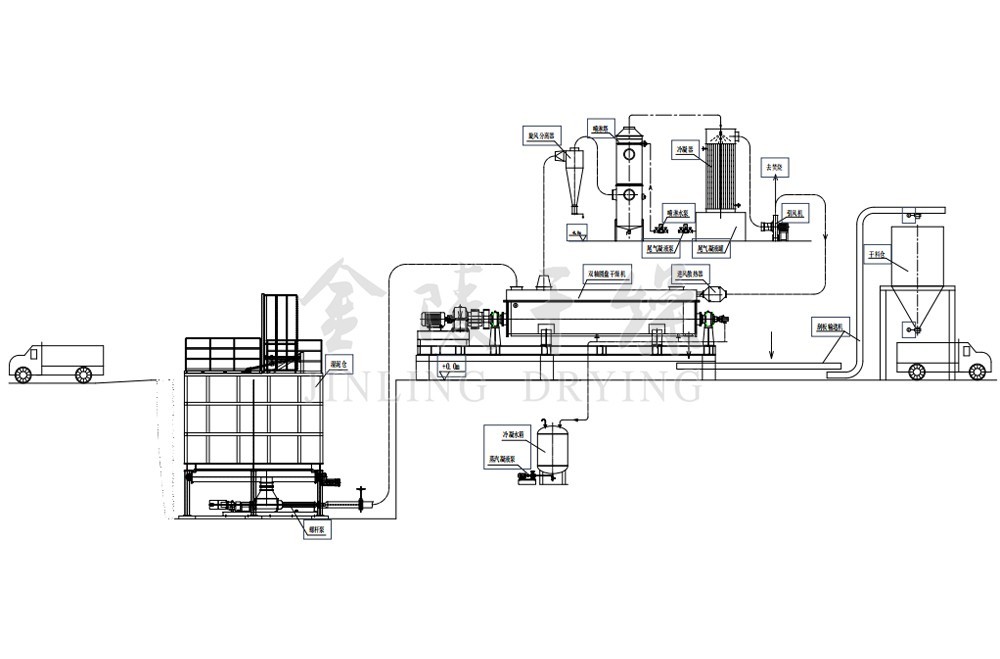

◆ Jinling Company is a professional manufacturer of vacuum disc sludge dryers; National Invention Technology (No. ZL 2013 2 0370333) 4) The first set of products in the country.

◆ Our company specializes in developing and designing a low-temperature closed and continuous drying process equipment for highly toxic and solvent containing flammable and explosive sludge. This not only adopts closed operation and condensation recovery, but also greatly improves safety; Moreover, while improving drying efficiency, it greatly reduces exhaust emissions, thus truly achieving the goals of safety, energy conservation, and environmental protection.

◆ Mainly used in chemical raw materials, pesticides, chemical sludge, etc. Specially designed for the drying treatment of oily sludge and coal chemical sludge, it is currently a substitute for imported equipment and one of the systems with high safety and stability in the sludge drying process.

◆ The oil containing sludge disc dryer innovatively designed and produced by the company in 2013 has been successfully applied.

◆ The company has independently innovated and designed various structural forms of vacuum disc drying processes, which have been widely put into production and application. The stability, efficiency, strength, continuity, and other aspects have been greatly improved;

◆ The equipment has a compact structure and occupies a small area. A single unit can be designed to produce large double axis or single axis disc dryers with an area of ≤ 500m2;

◆ High heat utilization rate, using conduction heating method, all heat transfer surfaces are covered by materials, reducing heat loss, and the heat utilization rate can reach over 85%;

◆ It has self-cleaning ability and can improve the heat transfer effect of the disc. The dispersing force generated by the combined motion of the inclined surface of the rotating disc and the particle or powder layer makes the sludge attached to the heating disc easy to fall off, and due to the reverse rotation of the dual axis blade, the alternating segmented compression and expansion of the stirring shear function, the heat transfer is uniform and the heat transfer efficiency is improved;

◆ It can achieve continuous, automated, and fully enclosed operations, reducing exhaust and dust emissions;

◆ Low exhaust emissions, thereby reducing the cost of exhaust treatment. Multiple exhaust treatment devices can be selected to meet emission standards;

The disc is an integral molded structure with few welds, smooth surface, low adhesion, low resistance, and low installation power;

Adopting high negative pressure or vacuum design to reduce boiling point and achieve the purpose of closed low-temperature drying operation;

◆ Overall reinforced design ensures better strength and service life;

The unique processing and assembly technology of Jinling Company ensures the concentricity of the equipment and superior sealing performance at both ends;

◆ Half tube jacket heating and integral jacket heating types can be designed according to different situations;;

Different discharge forms can be designed according to material requirements to ensure the drying retention time of materials and further improve overall efficiency.

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you

Jiangsu Jinling Drying Technology Co., Ltd. was founded in 2000, as an innovation-oriented enterprise specialized in advanced technology.We have over 30 years of experience in machine manufacturing. We have achieved more than fifty national level patents and ten provincial level certificates for new high-tech products. There are more than 120 employees in our factory, Jinling is professionally engaged in designing, manufacturing over 30 series of drying equipment, environmental protection equipment, evaporation & concentration equipment and dry granulation equipment which are widely used for environmental protection field, chemical field, food field, national defense field etc.

Jinling is the qualified manufacturer of special pressure vessel, established the biggest drying & granulating testcenter in China, and passed the examination of ISO 9001, ISO 14001, OHSAS18001 and CE certification.Jinling's equipment has been spread all over China and has been exported to over 40 countries.

1. Q: Jiangsu Jinling Drying Technology Co., Ltd is a manufacturer, trading company or a third party?

A: We are a manufacturer, Our company established in 2000.

2. Q: Where is your factory located?

A: Jinling is located in Changzhou city, Jiansu province, China. it is In the middle of Shanghai and Nanjing.

3. Q: How can I go to your factory?

A: You can fly to shanghai Pudong or Hongqiao international airport directly, then take the high speed train to Changzhou station (just 1 hour from Shanghai to Changzhou by train) and we arrange to pick you up at Changzhou station to go to our company. Yutong company is around 30km away from Changzhou station.

If you are in China now, you can fly to Changzhou Benniu airport, or take train or bus to Changzhou city directly .

We sincerely welcome to visit our company at any time.