YJG

JIANGSU JINLING DRYER

| Availability: | |

|---|---|

| Quantity: | |

Product Description

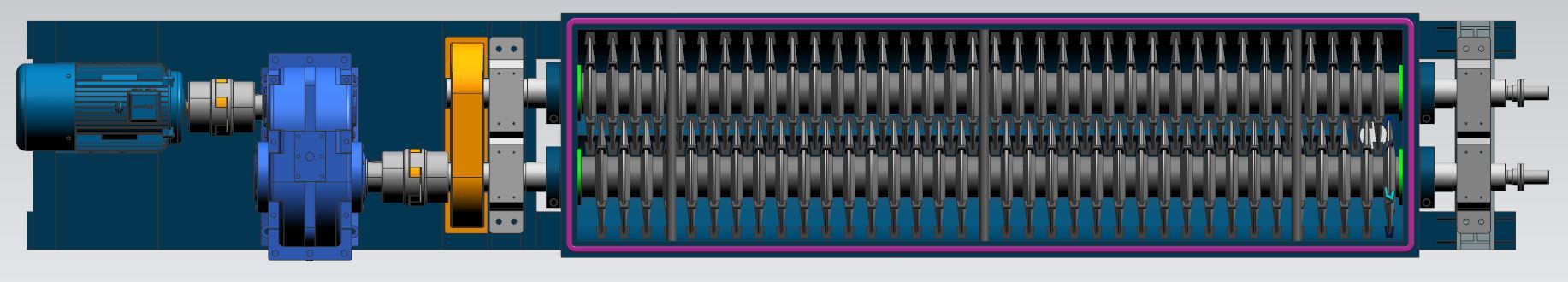

◆ This product is the second-generation disc blade sludge dryer independently developed and designed by our company, with different forms such as disc, semi disc, and spiral structure.

◆ The embedded stirring structure of two hollow shaft arranged heating disks is used to forcibly shear, crush, and disperse wet sludge. Scrapers at different angles are set on the periphery of each disk to provide self-cleaning function on the heat transfer surface (molded structure), fully improving heat and mass transfer and efficiency. Using steam or thermal oil as a heat source, it is directly introduced into the shaft, disc, and cylinder jacket, causing the moisture in the sludge to evaporate on the contact surface due to heating. At the same time, the gradient pushes the moisture in the sludge to transfer from the contact surface to the air and release it onto the sludge surface, thereby achieving the purpose of drying. The maximum daily processing capacity of a single drying machine is ≤ 150t (80%).

After years of development and application, the company has systematically optimized and improved the disc drying process and technology.

It can be used for sludge with different moisture and state (moisture content 50-95%)

The dual axis disc process and technology have been identified by experts as internationally advanced technology. The company has jointly developed it with Changzhou University and Tsinghua University, and improved and optimized the design application through systematic data simulation, strength calculation, gravity analysis and other means. The technical performance has reached the international advanced level, and the differential flow technology has been proposed for the first time internationally.

Jinling Company independently developed and designed a built-in reinforcement process, with some parts using automatic welding technology; Make the surface of the disc smoother and less prone to sticking, reduce leakage, improve welding performance and strength, and reduce welding attraction and deformation.

With the same sludge treatment capacity, due to the smaller diameter of the disc used, the linear velocity is lower and wear is reduced compared to the same period last year.

Jinling's unique design structure adopts a single head steam heating form to improve the service life of bearings, and the thermal expansion design is more stable.

| Configuration | Uniaxial or biaxial | |||||||||||

| Model | 5type | 15type | 20type | 40type | 60type | 80type | 100type | 120type | 150type | 200type | 320type | 420type |

| Heat transfer aream² | 5 | 15 | 20 | 40 | 60 | 80 | 100 | 120 | 150 | 200 | 320 | 420 |

| Host powerkw | 4 | 15 | 18.5 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | 132(Single axis) |

| Remarks | Using different materials and configurations according to the characteristics and requirements of different sludge | |||||||||||