HZG

JIANGSU JINLING DRYER

| Availability: | |

|---|---|

| Quantity: | |

Product Description

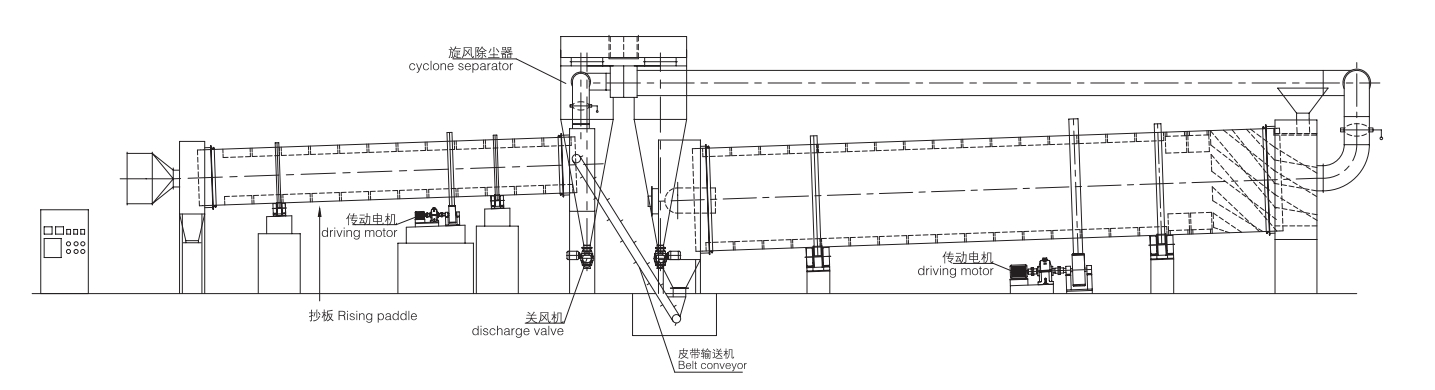

◆The rotary dryer has a cylindrical body that is slightly inclined. The rotation speed is adjustable within a certain range. The wet material is fed into the gylinder by the feeder. The material is evenly dispersed by the shoveling plates that are evenly distributed inside the cylinder. The hot air (cocurrent or countercurrent) passes through the gylinder and meets the material, which accelerates heat and mass transfer, so that the material can be dried in the end. Different shoveling plates will be used depending on the characteristics of the material. This machine has advantages such as simple structure, reliable operation, easy maintenance, and large processing capacity.

◆This machine is applicable for the drying large particles and materials with large specific gravity across chemical, mining, metallurgical and other industries, for example, ore, blast furnace slag, coal, metal powder, phosphatic frtilizer, ammonium sulfate, sludge, slime, etc.

◆This machine can also be used for drying powdery and granular materials with special requirements, for example, ore powder, lees, light calcium carbonate, activated clay, magnetic powder, graphite, and drug residuals.

◆For materials with large specific gravity and materials that require high temperature heating, the heavy-duty transmission or the thermal insulation for the gear is necessary, which shall be indicated in the orders.

◆Depending on the dust content of the exhaust gas, we can provide diferent dust removal devices, such as cyclone, cloth bag and water film.

◆The heat source can be electricity, steam, hot blast stove or waste heat.

| Model | 0.8-6 | 1.0-8 | 1.0-10 | 1.2-10 | 1.2-12 | 1.5-10 | 1.5-16 | 1.8-16 | 1.8-18 | 2-18 | 2-20 | 2.5-18 | 2.5-22 | 3-20 | 3-25 | 3.5-25 | 3.5-30 | |

| Rotary Drum | Diameter(m) | 0.8 | 1 | 1.2 | 1.5 | 1.8 | 2.0 | 2.5 | 3 | 3.5 | ||||||||

| Length(m) | 6 | 8 | 10 | 10 | 12 | 10 | 16 | 16 | 18 | 18 | 20 | 18 | 22 | 20 | 25 | 25 | 30 | |

| Slope(%) | 1-5 | |||||||||||||||||

| Rotation Speed (rpm) | 2-7 | 2-5 | 2-3 | 1-3 | ||||||||||||||

| Power of Motor (Approximate) (kW) | ~4 | ~5.5 | ~7.5 | ~11 | ~15 | ~18.5 | ~22 | ~30 | ~37 | ~45 | ~55 | ~75 | ~90 | |||||