Rotary drum dries sludge using waste heat, special crushers for quick water evaporation. Larger particles stay longer; exhaust treated to meet standards. Innovations: tailored crushing, sealing, bearing cooling, indirect heating. Ensures efficiency, longevity, compliance.

Jiangsu Jinling Drying

841939990

| Availability: | |

|---|---|

| Quantity: | |

Product Description

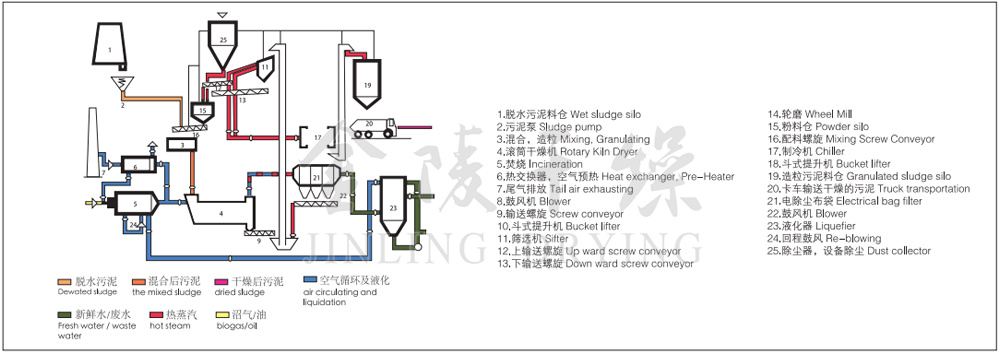

Rotary drum drying is a widely used method for reducing moisture in materials like sludge. Waste heat or heat exchange air enters the dryer, directly exchanging heat and mass with wet sludge in the channel. This ensures rapid evaporation while maintaining high operational efficiency.

The rotary drum dryer is equipped with a specialized crushing device tailored to its structure, enabling rapid water evaporation from sludge. Smaller particles discharge efficiently with gases via an outer channel, while larger particles remain inside until fully dried.

Exhaust gases are treated using deodorizers or water foam dust removal systems to meet environmental standards before release, ensuring eco-friendly operations.

Customized dispersion and crushing tools are applied at different stages of sludge drying, boosting efficiency and energy savings based on material characteristics.

Advanced sealing materials prevent leaks, enhance equipment lifespan, and reduce maintenance needs for sustained reliability.

Integrated cooling devices lower bearing temperatures during continuous operation, extending component lifespan and preventing overheating.

Indirect heating minimizes exhaust volume and improves heat utilization, optimizing energy efficiency and sustainability.

Custom sheet cutting forms adapt to material states, reducing bonding and ensuring smooth processing for higher-quality output.

Material-specific feeding mechanisms prevent blockages, enabling uninterrupted operations and consistent drying performance.

Capacity: Model-dependent, scalable for industrial needs.

Efficiency: High drying rates via advanced airflow and heat exchange design.

Energy Consumption: Optimized for minimal power usage.

Maintenance: Low upkeep requirements due to durable construction.

Adjustable parameters (temperature, speed, airflow) allow efficient drying of diverse sludge types, from industrial to municipal.

Deodorizers and water foam dust removal technologies treat exhaust gases, eliminating odors and pollutants to meet global standards.

Robust cooling systems and high-quality seals enable 24/7 operation. Regular maintenance ensures long-term reliability.

| Conditions | Feed moisture content% | 80 | ||

| Discharge moisture content% | 40 | |||

| Material outlet temperature ℃ | 90 | |||

| Inlet air temperature (with hot blast stove) ℃ | 500 | |||

| Air outlet temperature ℃ | 100~130 | |||

| Material data | Feeding amount t/d | 50 | 100 | 200 |

| Water evaporation rate t/d | ~33 | ~66 | ~132 | |

| Production volume t/d | ~17 | ~34 | ~68 | |

| Installed power kw/h | ~70 | ~110 | ~200 | |

| Host external dimensions (reference) mm | 24000×3500×5500 | 34000×4000×6500 | 44000×5000×8500 | |

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you

Jiangsu Jinling Drying Technology Co., Ltd. was founded in 2000, as an innovation-oriented enterprise specialized in advanced technology.We have over 30 years of experience in machine manufacturing. We have achieved more than fifty national level patents and ten provincial level certificates for new high-tech products. There are more than 120 employees in our factory, Jinling is professionally engaged in designing, manufacturing over 30 series of drying equipment, environmental protection equipment, evaporation & concentration equipment and dry granulation equipment which are widely used for environmental protection field, chemical field, food field, national defense field etc.

Jinling is the qualified manufacturer of special pressure vessel, established the biggest drying & granulating testcenter in China, and passed the examination of ISO 9001, ISO 14001, OHSAS18001 and CE certification.Jinling's equipment has been spread all over China and has been exported to over 40 countries.

1. Q: Jiangsu Jinling Drying Technology Co., Ltd is a manufacturer, trading company or a third party?

A: We are a manufacturer, Our company established in 2000.

2. Q: Where is your factory located?

A: Jinling is located in Changzhou city, Jiansu province, China. it is In the middle of Shanghai and Nanjing.

3. Q: How can I go to your factory?

A: You can fly to shanghai Pudong or Hongqiao international airport directly, then take the high speed train to Changzhou station (just 1 hour from Shanghai to Changzhou by train) and we arrange to pick you up at Changzhou station to go to our company. Yutong company is around 30km away from Changzhou station.

If you are in China now, you can fly to Changzhou Benniu airport, or take train or bus to Changzhou city directly .

We sincerely welcome to visit our company at any time.