QG

JIANGSU JINLING DRYER

| Availability: | |

|---|---|

| Quantity: | |

Product Description

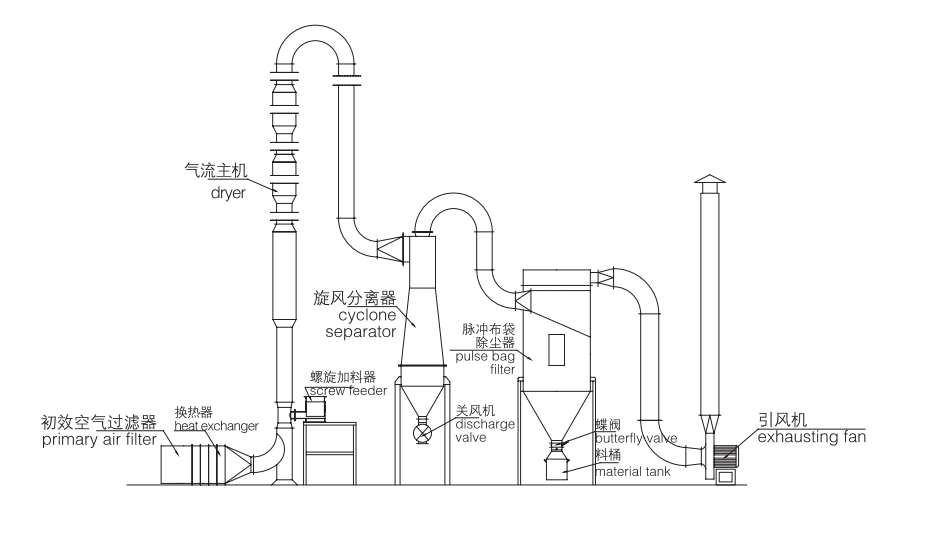

◆The materal is fed into the flash dryer quantitatively through the feeder. The heated air with high velocity transfers heat quickly to the powdery material in the drying pipe. The dried material is continuously discharged after being collected by the cyclone separator, and the humid air is discharged through the induced draft fan. The cloth bag dust collector or the water film dust collector can also be added to the machine. Dust explosion should be prevented for fine materials.

◆This equipment is suitable for drying or cooling powdery and granular materials with low viscosity, and it is also applicable for continuous mass operations.

methaqualone, intermediate, resin, ASC, white carbon black, phenylpyrazolone, oxalic acid catalyst, rubber catalyst, calcium formate, precipitated carbon powder, paracetamol, p-aminosalicylic acid, dormato, terephthalic acid, diethylaniline, titanium dioxide, activated carbon, sodium fluosilicate, fluorite, ammonium sulphate, silicone powder, synthetic resin, calcium sulfonate, polypropylene resin, aureomycin, sodium pyrosilicate, coffee residuals with mucochloric acid, oral glucose, sodium sulfate,sulfide ore, phosphate rock powder, PVC, tetracycline, starch, calcium carbonate, ilmenite, bean powder, stearate, zein , medicines, wood chips, iron oxide, wine residuals and other products.

| Model | Evaporated Moisture (Approximate)(kg/h) | Power (kW) | Floor Space Reouired (m²) | Height ((m) |

| QG 50 | ~50 | ~7 | ~20 | ~14 |

| QG 100 | ~100 | ~13 | ~32 | ~14 |

| QG 200* | ~200 | ~21 | ~40 | ~15 |

| QG 250 | ~250 | ~24 | ~64 | ~15 |

| QG 500 | ~500 | ~43 | ~96 | ~18 |

| QG1000* | ~1000 | ~100 | ~120 | ~18 |

| QG 1500* | ~1500 | ~150 | ~200 | ~20 |