Views: 0 Author: Site Editor Publish Time: 2025-06-26 Origin: Site

In the feed industry, drying plays a crucial role in ensuring product stability, shelf life, and bioavailability. The drum scraper dryer, also known as a drum flaker dryer, offers an efficient, continuous, and cost-effective solution for drying high-viscosity feed additives such as amino acids, enzymes, and nutritional supplements. This advanced drying technology is widely used in feed additive processing plants due to its compact structure, high heat transfer efficiency, and ease of operation.

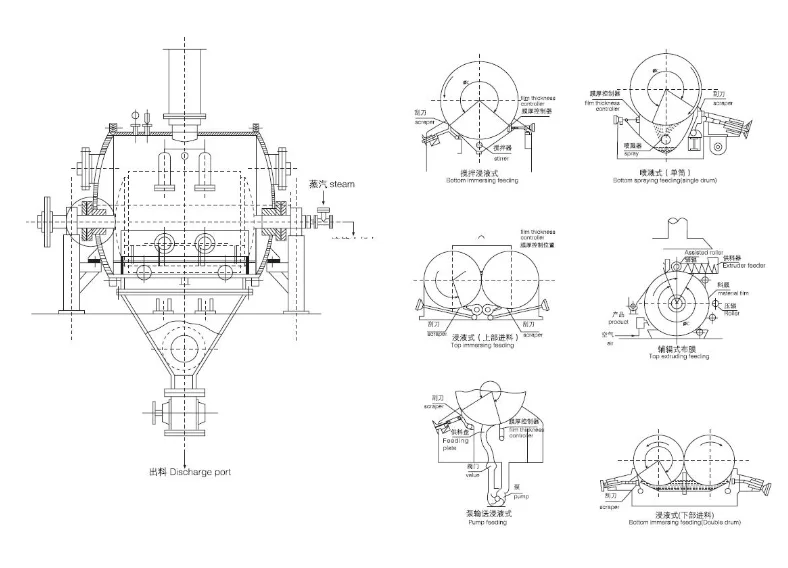

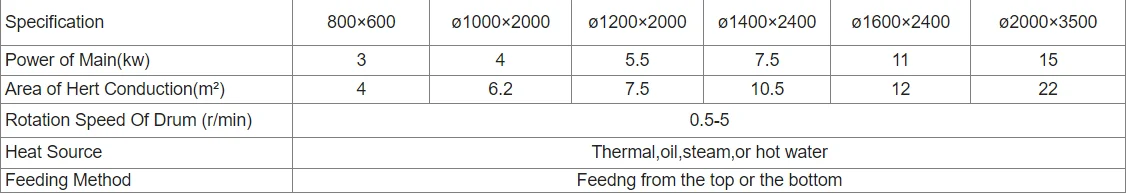

A drum scraper dryer consists of a hollow rotating drum heated internally by steam or hot water. Liquid or slurry feedstock is applied as a thin film onto the drum surface via a feeding device. As the drum rotates, the film dries quickly under heat. A set of adjustable scrapers then continuously remove the dried material from the drum surface.

Hollow drum (304/316L stainless steel): Provides excellent corrosion resistance and uniform heat distribution.

Scraper blade: Adjustable and made from hardened steel or PTFE, ensuring clean removal of the dried layer.

Feeding system: Can handle viscous, sticky, or paste-like materials.

Condensate removal and heating system: Maintains consistent drying temperature and energy efficiency.

The drying film thickness on the drum is minimal (0.3–1.5mm), allowing for rapid heat transfer and short drying time. This protects heat-sensitive nutrients, enzymes, and other bioactive substances commonly found in feed additives from degradation.

Unlike batch dryers, the drum scraper dryer offers a continuous drying process, increasing productivity and reducing labor costs. The consistent drying mechanism ensures uniform moisture content, which is essential for regulatory compliance and downstream mixing.

This drying system occupies a smaller installation space compared to spray dryers or vacuum ovens. Its low energy requirement and use of low-pressure steam make it economical and environmentally friendly.

Suitable for viscous pastes, slurries, and thermal-sensitive materials.

Inner contact surfaces are made from food-grade stainless steel (SS304 or SS316L), compliant with feed hygiene regulations.

Drum speed, steam pressure, and scraper position can be adjusted to optimize drying results.

Ideal for customized production lines with varying formula needs.

Designed with CIP (Clean-In-Place) systems for hygienic processing.

Simple mechanical structure allows for fast maintenance and low downtime.

Amino acids (lysine, methionine)

Enzyme preparations

Mineral premixes

Plant extracts

Vitamin blends

Organic acids

Each of these additives requires specific drying conditions to maintain functional performance, all of which can be fine-tuned using the drum scraper dryer.

| Feature | Drum Scraper Dryer | Spray Dryer | Vacuum Dryer |

|---|---|---|---|

| Heat Efficiency | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ |

| Space Usage | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ |

| Cost of Operation | ★★★★☆ | ★★☆☆☆ | ★☆☆☆☆ |

| Suitable for Sticky Material | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ |

| Cleaning & Maintenance | ★★★★☆ | ★★★☆☆ | ★☆☆☆☆ |

Our drum scraper dryers have been exported to over 30 countries, including the United States, Vietnam, Russia, Brazil, and Indonesia. They are widely used in feed additive manufacturing, chemical processing, and food industries.

Whether you operate a feed mill, a nutritional product plant, or a biotech facility, our drying equipment can be integrated into your production line with customized voltage, capacity, and materials of construction.

Design customization based on feedstock properties.

Trial testing services available before bulk order.

1-year warranty and lifetime technical support.

Multi-language manuals and remote installation support.

A drum scraper dryer is an optimal solution for drying feed additives that are heat-sensitive, sticky, or paste-like. With high efficiency, compact design, and customizable features, it has become the preferred drying system for feed additive manufacturers globally.